The Legacy project aims to create a lasting positive impact on the planet by ensuring safe underground storage of CO₂ without the risk of dangerous leaks through former oil and gas wells.

These old wells could leak if they are not properly sealed. Legacy’s mission is to develop innovative ways to verify the integrity of these wells, fix potential issues, and ensure the CO₂ remains securely contained underground.

The project mainly focuses on abandoned wells, although the same techniques can also be applied to wells still in use.

“That’s a simpler problem because if the wells are not abandoned, it’s much easier to access them and bring tools inside the borehole. This provides us with data that is closer to what we need,” says Bastien Dupuy, the project coordinator for Legacy.

Peder Eliasson is the project manager and also participated in the interview.

The Norwegian-led consortium includes research partners from France and the US, as well as four industry partners. The Legacy project began in 2024 and will run for three years until the end of 2026, during which the team will develop tools, software, and workflows to make screening, characterisation, and monitoring of wells—along with leakage modelling and remediation—faster and more reliable worldwide.

Dupuy explains that much of the current work involves numerical modelling, as many of the tools being tested are new and require careful validation.

Cutting Costs

One of the main goals is to make assessment of abandoned wells significantly cheaper.

“The idea is that characterisation by re-entering a well that has already been plugged and abandoned would normally be extremely expensive compared to the non-invasive methods that Dupuy and the team are developing,” Eliasson explains.

By using external (non-invasive) methods, the project aims to avoid physically reopening wells, simplifying the inspection process and lowering costs and risks.

Eliasson adds that the Legacy project also includes a work package focused on improving future well-abandonment practices to make long-term monitoring easier.

“For example, we can equip wells with fibre optics before placing cement plugs,” Dupuy adds. “That helps us observe what happens over the next 10, 20, or 30 years.”

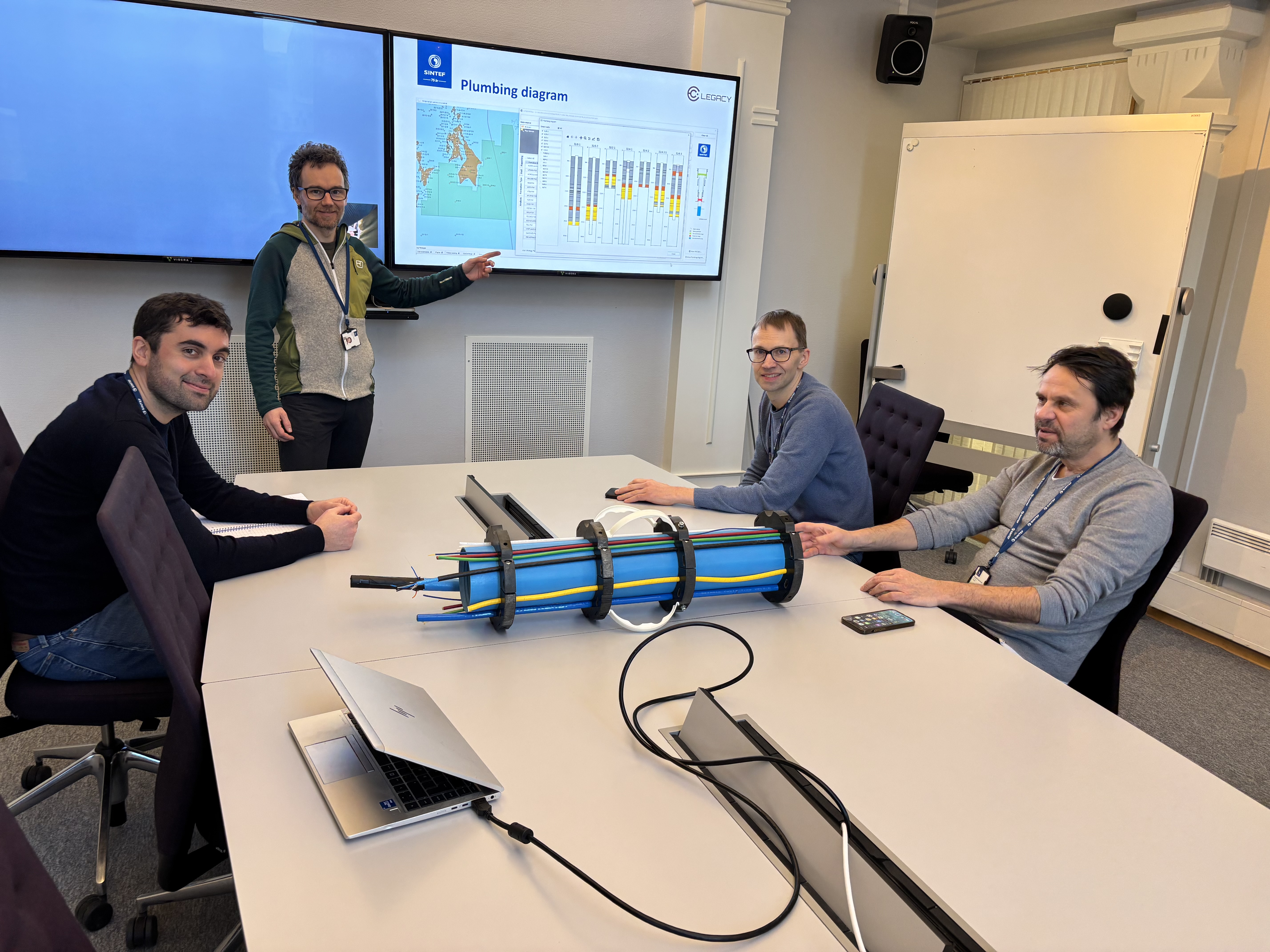

From left to right: Nicolas Barbosa, Bastien Dupuy, Peder Eliasson, Benjamin Emmel are all part of the core team of the LEGACY project.

On the table, the blue cylinder is an example of a well casing instrument with distributed fiber optics that are used for monitoring well integrity. Photo Arnt Grøver

Industry Involvement

A key objective is to engage industry partners in adopting Legacy’s methods. Dupuy acknowledges that it “costs some money” to re-enter wells but emphasises that by installing monitoring instruments, companies can save significantly on long-term CO₂ storage surveillance, reduce the risks and improve public acceptance. The importance of the work is also confirmed by a growing interest from industry.

“We are collaborating with French companies who visited Norway to work at our ECCSEL Svelvik CO2 Field Lab site, a small CO₂ injection facility near Oslo. We carried out experiments there in 2025 and will now analyse the data together,” Dupuy says.

He also notes that forthcoming EU regulations will require oil and gas companies to ensure their legacy wells are properly assessed to eliminate leakage risks.

Valuable Partnerships

Dupuy highlights the importance of being part of the CETPartnership, both for securing funding and building connections with other projects in the same field.

He, Eliasson, and their team are now looking to secure funding for a follow-up project, expected to run from 2026 to 2029. They have already begun discussions with industry partners about potential co-financing.

“Despite a somewhat reduced industry appetite for CCS research for the moment, we still believe that the industry interest in this particular topic will result in several storage operators also supporting a follow-up project.”